US DEPARTMENT OF ENERGY STUDY SHOWCASES DESTRATIFICATION EFFICIENCIES

Falling temperatures outside can wreak havoc on the comfort and energy-efficiency inside a commercial building.

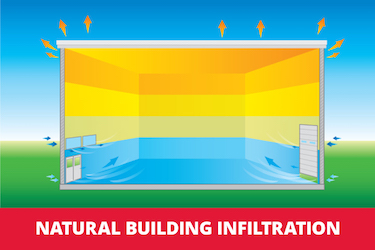

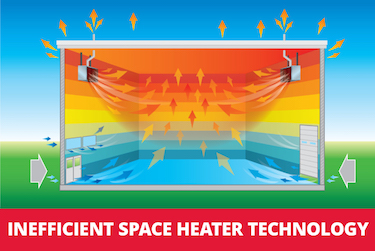

Heat, in any season, rises. But in winter, when it’s required for comfort, we depend on it to be cascaded low, throughout the building to occupants on the floor. Too often, however, older HVAC systems struggle to evenly distribute warmth where it is needed. As they work overtime to keep up with cold outdoor temperatures seeping in through open doors, rising heat escapes through the roof in a process known as stratification.

Industrial facilities and high-bay distribution centers are particularly at risk for the lost energy and discomfort of stratification. When heating a high-bay facility, it is critical to use one or more destratification technologies.

Destratification Options for High-Bay Buildings

Recirculation with large blowers, or destratification fans, are one way to accomplish this. High-temperature heating and ventilation technology, or HTHV, is another solution, particularly for building managers looking to maximize operations budgets and equipment space.

HTHV systems utilize 100% outside air, heat it to a maximum of 160 degrees and then discharge it via high-velocity blowers built into the unit. The use of 100-percent outdoor air makes HTHV a viable choice for ventilation, and the built-in blowers are strong enough to address stratification issues. This reduces the need for the significant horsepower of recirculation systems or additional equipment, such as high-volume, low speed fans, ultimately lowering installation costs associated with unit counts, gas piping, electrical runs and labor.

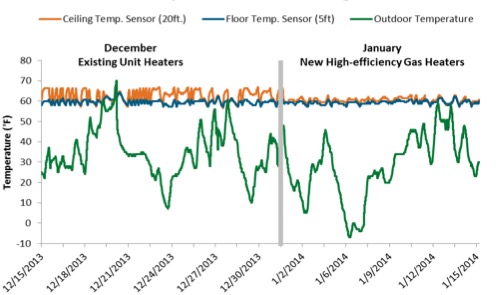

DOE study also shows destratification capabilities of HTHV

In 2014 the U.S. Department of Energy conducted a field study to determine the energy savings potential of HTHV technology compared to that of standard unit heaters. The study ran for four months, November through February, were each solution was used in alternating months. As part of the project the DOE also wanted to study the destratification capabilities of HTHV. To do this the DOE placed data loggers within the 24-foot-tall building. The data loggers collected data during the study and the HTHV technology showed improved temperature control over conventional equipment by reducing thermal stratification between the floor and ceiling. Figure 1, in the graph below, displays the difference in temperature near the floor (5 ft. off the floor) and at the ceiling (20 ft. off the floor) during the monitoring period. For buildings with high ceilings, such as the warehouse in this demonstration, warm air naturally rises to the ceiling and can raise the average ceiling air temperature Δ10-20°F above the thermostat set-point. Because of this temperature gradient, the heating system must run longer and consume more energy to meet the needs of the building’s occupants near the floor. As demonstrated by the temperature differential between floor and ceiling in Figure 1, the HTHV gas heaters eliminate much of the temperature stratification experienced with the existing unit heaters. Generally, the existing gas heaters exhibited vertical temperature differences of more than Δ8°F higher than exhibited by the high-efficiency gas heaters. HTHV direct-fired gas heaters and other destratification technologies increase air circulation and provide more uniform temperature distribution throughout the space. Additionally, because the roof is typically the largest area for heat transfer in a warehouse, lowering the temperature of the interior ceiling decreases the heat loss through the roof.