ELECTRIC VS. GAS HEAT

A deep dive in to the practicality of Electric heat vs. Gas heat in large spaces.

INTRODUCTION:

Large spaces such as warehouses can be efficiently heated with natural gas. High efficiency direct gas fired heating equipment (92% efficient) is highly practical for these spaces - particularly those with high heat demands - as the high heat content per CFM of outside air that can be delivered results in relatively few units being required to meet a building’s heat load.

Recently, some localities and states have implemented or are considering legislation or building code changes that prohibit or severely restrict natural gas usage, requiring electrification as a means of carbon footprint reduction. However noble these pursuits may be, they neglect the practicality of electrical infrastructure capacity constraints and the steep increase in electrical service requirements that result from natural gas / propane prohibitions. The purpose of this paper is not to debate whether natural gas should be prohibited, but rather to discuss the practical implications of heating large spaces with electric instead of natural gas and to submit that gas fired heating equipment is a historically reliable and effective means of decarbonization.

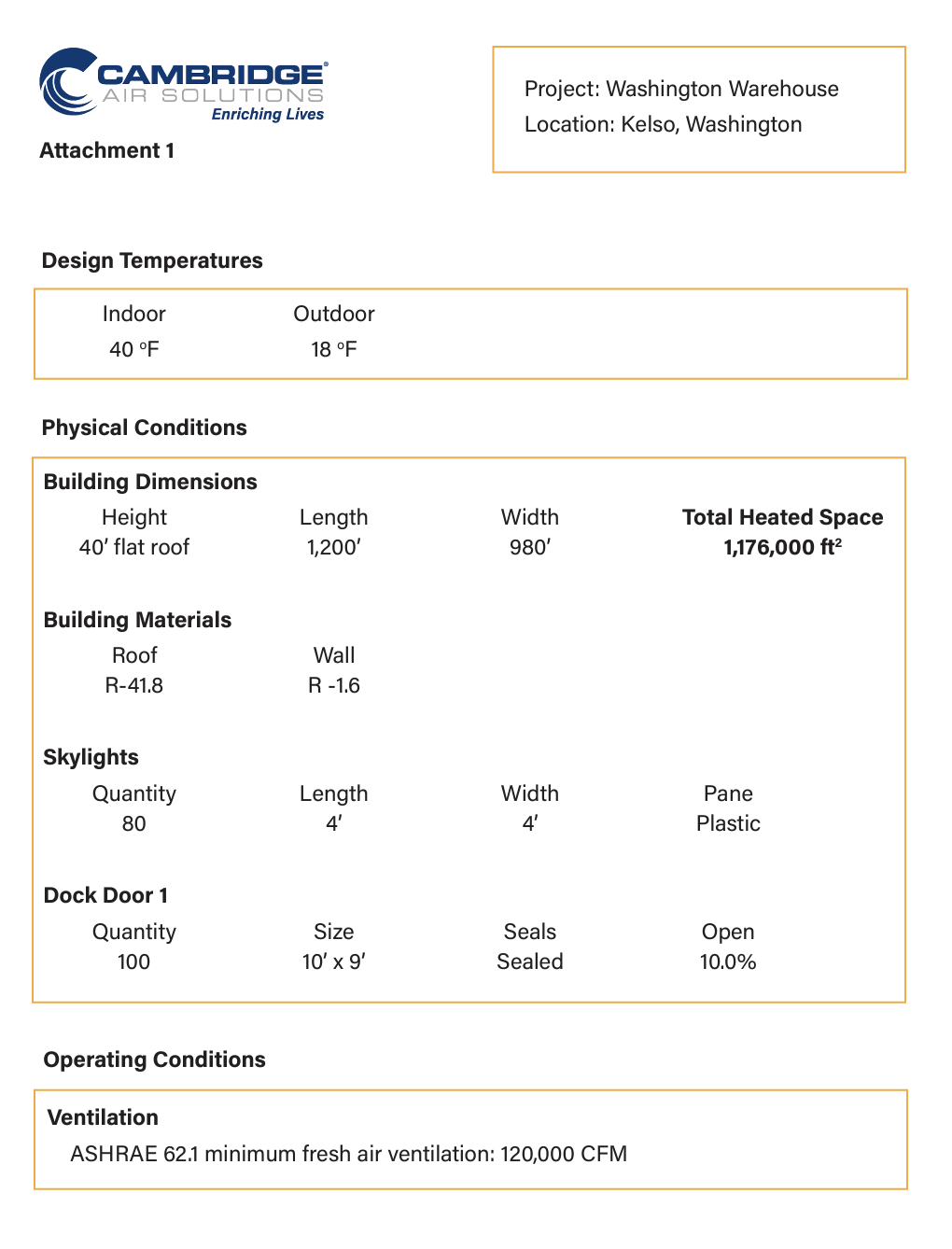

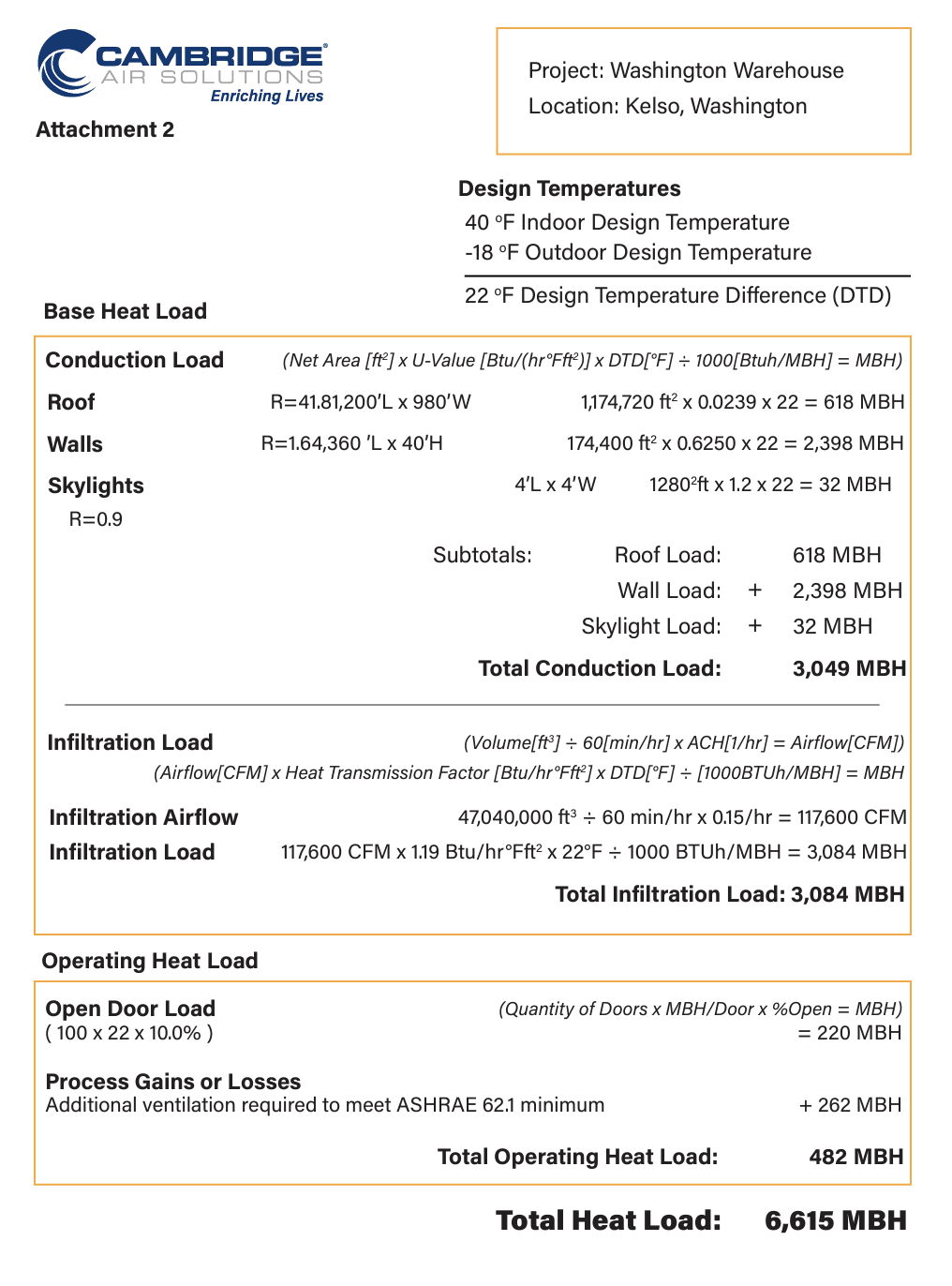

To understand the implications of using electric heat in lieu of natural gas fired equipment, a sample 1.1M square foot warehouse located in Kelso, Washington with characteristics shown in Attachment 1 will be considered. With the following design conditions, the subject building has a total heat load of 6,615 MBH (detailed calculations are shown in Attachment 2).

Freeze protection inside design temperature.......40°F

Outside design temperature...................................18°F

ASHRAE 62.1 minimum ventilation ........................120,000 CFM

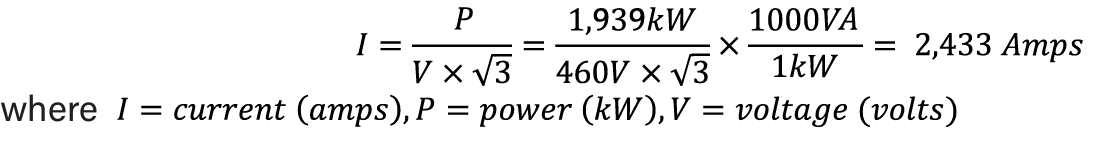

Total Building Heat Load.............................6,615 MBH = 1,939 kW 1

This heat load represents 5.6 BTU per square foot for the subject building. Electrical service of 460V/3PH is common for these types of buildings and is assumed for this analysis. At 1,939 kW, the building requires 2,433 amps of electrical service for heating alone.

The actual building requirement will exceed this after accounting for lighting, blower fans, conveyors, process equipment, and other necessary building systems or newly legislated electrified components.

Building owners and engineers can use this information to determine the practicality of electrical service requirements when initially specifying a building and the type of heating equipment. Other considerations include the relatively fewer number of natural gas units required to heat a building.

For the subject building, an average of six direct fired natural gas Cambridge units could meet both the building’s ventilation and heat load whereas a minimum of thirty two 60kW electric unit heaters would be required to similarly meet the building’s heat load.For the subject building, an average of six direct fired natural gas Cambridge units could meet both the building’s ventilation and heat load whereas a minimum of thirty two 60kW electric unit heaters would be required to similarly meet the building’s heat load.

Some engineers use an additional 10-20% more unit heaters than necessary to meet the heat load to overcome unit heater system inefficiencies and destratification limitations. Additionally, other equipment would be needed to address the outside air ventilation requirement. It should not be discounted the environmental impact and cost of manufacturing, transporting, installing, and maintaining this extra equipment simply for the sake of not using natural gas. Ongoing utility costs for electric heat are over double what they are for a functionally equivalent natural gas heating system (for the above scenario at the design condition, electric and natural gas costs would be $233 and $99 per hour respectively)2.

Even more disconcerting is that every equivalent unit of heat produced by an electric heater emits 58% more carbon dioxide than does natural gas after factoring in local emission rates for electricity generation in Kelso, WA.

According to the Environmental Protection Agency:

-

Electricity in Kelso, Washington has a CO2 emission rate3 of 634 lbs / MWh

-

Natural gas has a CO2 emission rate4 of 11.7 lbs / therm of natural gas

Put in equivalent terms with a conversion of 34.1 therms per 1 MWh:

-

Electricity in Kelso, Washington has a CO2 emission rate of 634 lbs / MWh

-

Natural gas has a CO2 emission rate of 399 lbs / MWh

The above analysis considers a modest outside design temperature and the minimum possible inside design temperature (i.e., freeze protection applications) – additional heating requirements will only worsen the situation. Furthermore, outside design conditions can be significantly lower in other locations. For example, Spokane’s winter design temperature is 6.1°F, but many engineers design for 0°F to include safety factor and global temperature fluctuations. Furthermore, certain inventory and equipment can require higher minimum indoor design temperatures. Perhaps more importantly, the health and wellbeing of employees (and the corresponding attrition resulting from poor working conditions) can justify comfort heating applications in which indoor design temperatures can exceed 60°F.

Using the same method and building as shown above but instead located in Spokane, the electrical service requirement for heating alone is shown below:

Inside design temperature........................................40°F

Outside design temperature.....................................0°F

ASHRAE 62.1 minimum ventilation.........................120,000 CFM

Total Building Heat Load..............................12,027 MBH = 3,525 kW5

Electric Heat Amperage Requirement........4,424 amps

Similarly, for a comfort heated building in Kelso:

Inside design temperature.......................................65°F

Outside design temperature....................................18°F

ASHRAE 62.1 minimum ventilation.........................120,000 CFM

Total Building Heat Load..............................14,132 MBH = 4,142 kW6

Electric Heat Amperage Requirement........5,198 amps

And lastly, for a comfort heated building in Spokane:

Inside design temperature.......................................65°F

Outside design temperature....................................0°F

ASHRAE 62.1 minimum ventilation.........................120,000 CFM

Total Building Heat Load..............................19,544 MBH = 5,728 kW7

Electric Heat Amperage Requirement........7,189 amps

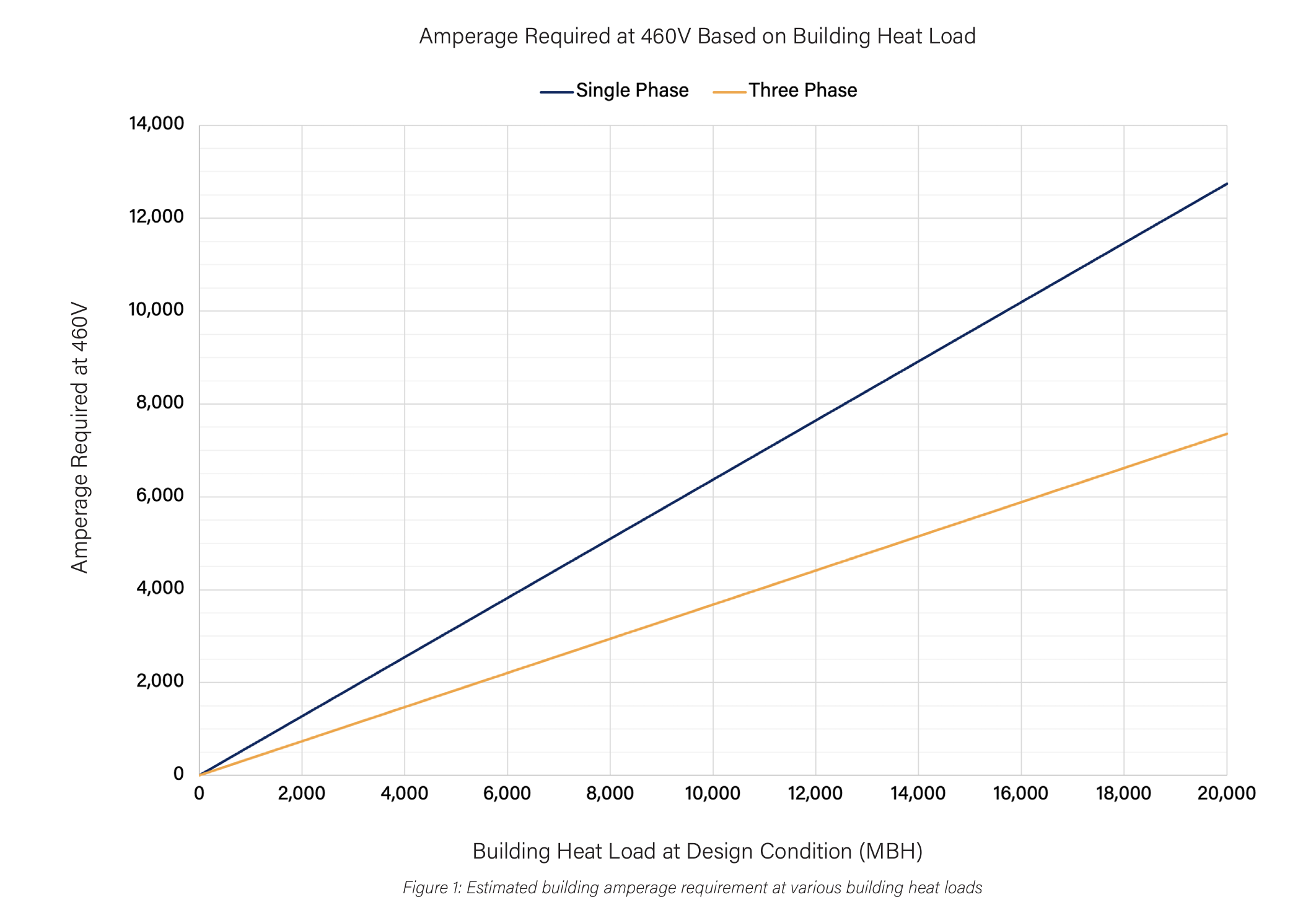

The electrical amperage requirement at any given heat load can be quickly estimated using the chart below in Figure 1. For buildings with large heat load requirements resulting in heat inputs exceeding 8 BTU / square foot, other factors such as increased insulation or reduced minimum ventilation must be considered to meet semi-heated space restrictions, where applicable.

These results show the exceedingly high electric service requirement that results from a decision to use electric heat instead of natural gas and how the requirement varies depending on where a building is located and the associated design conditions. The practical implications of electrical heat vary greatly based on design temperature difference and are exacerbated by the relatively greater number of electric heating equipment required to simply heat a space.

Highly efficient direct gas fired heating equipment is more practical than electric heating equipment and serves as a means of decarbonization given its 92% ef ficiency rating

While in some cases electric heating may indeed be appropriate, its use is not suitable for all applications and natural gas prohibitions should not be indiscriminately implemented without considering the large building heating and ventilating nuances discussed herein.

Want to discuss more so you can make the right choice for your facility? Click here to find a representative for a free Energy Use Analysis!

DOWNLOAD WHITE PAPER PDF