Factory Cooling Solution for California Box Manufacturer: A Success Story

Founded as a small family business in 1973, Pacific Southwest Container (PSC), started with one factory serving local businesses in Modesto, California. Three generations later, they have grown to be one of the largest privately-held packaging companies in the United States. With more than 1,000 team members and four locations, they create packaging that ranges from high-volume to high-touch, from standard to sophisticated. They remain committed to investing in innovation, their people, and their craft.

Problem:

Providing proper indoor air quality during hot summer months can be challenging for most manufacturers throughout the U.S. But, when your facility has several corrugating machines operating year-round, and you are in the San Joaquin Valley in Visalia, California, providing proper indoor air quality for your hard-working team is a huge challenge.

For this West Coast corrugated box manufacturer, the heat created during the manufacturing process is enough to drive the temperature inside the facility to uncomfortable levels and a factory cooling system was required to improve worker comfort and productivity. Add in the need for mechanical ventilation to provide fresh air, and now you are introducing outside air where the temperatures during the summer can reach 100°F and higher.

Hot air from the outside combined with hot temperatures created via your process means your facility is hot — with no relief in sight.

How does a major west coast corrugator provide superior IAQ for their team without breaking the bank? The answer: a direct evaporative factory cooling solution from Cambridge Air Solutions.

Solution:

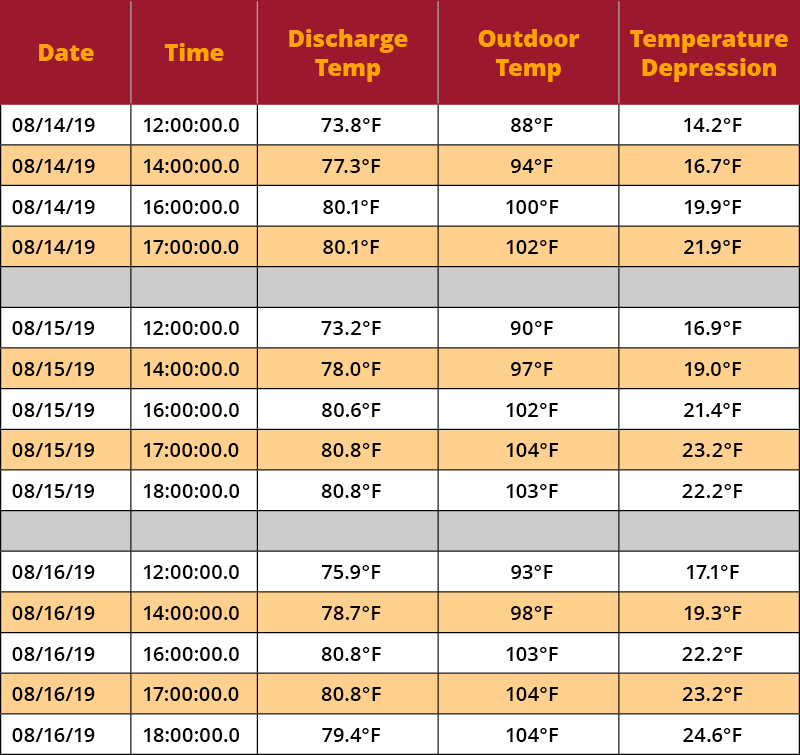

The hot dry climate of the Pacific Southwest is perfect for Cambridge Air Solutions’ direct evaporative cooling technology. On a 104°F day, you can achieve a 24°F temperature depression from the outside air. That’s a “leaving-air” temperature of 80°F when it’s 104°F outside.

Now, that doesn’t mean your facility will be 80°F during operating hours. What is does mean is your factory cooling solution is matching your exhaust air load with 80°F cool-tempered air. Mix that with the heat your corrugating machines create (and other heat generating processes within the facility), and you now have a facility with dramatically lower air temperatures. This gives you the ability to better manage your IAQ versus bringing in 105°F air and mixing that with the already warm air inside your facility. In other words — better indoor air quality for your hard-working people.

Results:

Direct Evaporative Cooling:

The Cambridge E-Series DEC unit is engineered to provide cool, fresh, tempered air for facilities to create a more comfortable and productive work environment while using up to 70% less energy than conventional mechanical factory cooling systems.

The E-Series unit has 10 models, supplying from 10,000 to 80,000 CFM of outside air. These compact units are built in modular sections with a continuous perimeter base frame. They can be rooftop or grade mounted. They ship in one section for quick and easy installation saving both time and money.

Industrial applications for the E-Series (Direct Evaporative Cooling) include:

Commercial

- Warehouse/Distribution

- Aviation

- Sports Arenas

- Greenhouses

- Agriculture

- Municipality

Industrial

- Manufacturing

- Warehouse

- Waste Water Treatment

- Foundries

Discover the Cambridge E-Series

Evaporative cooling systems have several benefits. They use only a fraction of the energy of typical compressor-based cooling systems. The highly efficient Cambridge E-Series evaporative cooling system can reduce energy use by 70%. (The actual savings will vary with the type of evaporative system and the climate.) For dry climates, where evaporative cooling can meet the entire load, they dramatically reduce peak-demand. Moreover, since they use 100% outside air for cooling, the right factory cooling system can improve indoor air quality as well. Learn more about the Cambridge E-Series direct evaporative cooling units.

Factory Cooling Solutions for Manufacturers

Each manufacturing facility has different specifications that require unique factory cooling solutions. Cambridge Air Solutions installs world-class evaporative cooling systems that are designed to meet all system requirements in order to provide energy efficiency and optimal thermal comfort for workers. Our team of experts work tirelessly to identify and resolve the challenges associated with high-bay manufacturing facilities. Learn more about our factory cooling, heating, and ventilating solutions for manufacturers.